3D scanning Part A: Potential and possibilities

3D scanning techniques have found significant applications in various fields of activities including building, infrastructure, material science, manufacturing, automotive, aerospace, art and others. Their main uses involve 3D printing drawings acquisition, Quality Assurance, maintenance, conservation of rare objects, restorations, and others.

3D scanning technologies include various methodologies to acquire 3D images of existing objects. 3D scanning approaches can be categorized in the following categories, depending on various factors as described in Table 1.

Table 1: 3D scanning approaches depending on different attributes

| Construction |

Stationary – large size, bound to one location |

|

Portable – small size, ‘bring-to-object’ principle |

|

| Scanning method |

Contact – mostly stationary scanners with coordinate measuring machines [CMM] and measuring arms |

|

Non contact – laser scanners, optical scanners, X ray diffraction scanners and other technologies |

|

| Specific scanning principle |

Optical – based on the photographic principle. An object is photographed by various angles and the combination of 2D data lead to a 3D image. Advantage: color acquisition |

|

Laser – based on the triangulation principle. A laser beam falls onto a surface and the time of flight is used to acquire the shape of the surface |

|

|

Ultrasound – Based on the flight of time and triangulation like the laser based scanners. Different in resolution [0.3 – 0.5 mm], less effective that laser ones |

|

|

X ray RTG – X ray diffraction and adsorption measurement lead to accurate in depth measurements of the whole volume of an object. X ray offers unique information on internal structure, layering, defects and other important properties very important for specific applications such as 3D printing, restoration and others |

|

|

Mechanical – based on CMM and measuring arms, a portion of a surface is scanned |

|

|

Destructive – an object is skinned layer by layer to acquire all 3D internal structure |

|

| Application areas |

Reverse engineering – for object reconstruction and preservation |

|

Quality control – acquisition of working behavior, requirements for maintenance and replacement |

|

|

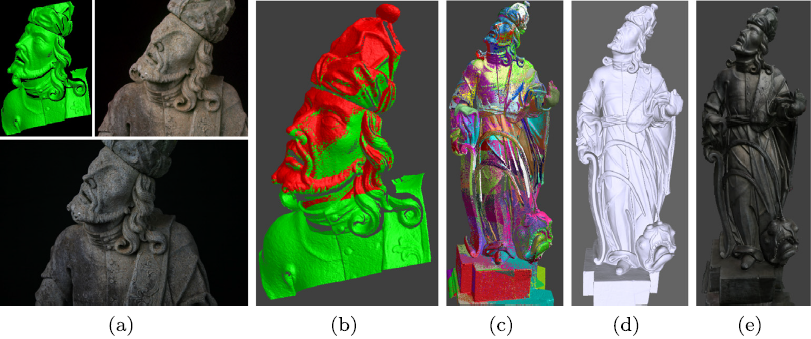

Art and architecture – visualization of large buildings, restoration needs, digitization of historical sites and artefacts, creation of learning databases and platforms, creation of educational copies, creation of replicas for exhibitions, partial modifications and others |

|

|

Multimedia - Creation of educational material, creation of scientific simulations, games and others |

|

|

Medicine – reconstruction of human parts, visualization of human parts, identification of disease states and others |

Various other analytical techniques have been reported for structure acquisition and utilized with novel scanners. Among them the most important are:

- - Raman spectroscopy. Due to size requirements can only be applied to small scale objects

- - Atomic absorption. Based on bombardment of the scanned object with various small size atoms and subsequent measurement of absorption amounts and intensities

- - Small angle X ray scattering. Especially important for organic derived parts such as wood, bones, polymers [inhomogeneous and anisotropic materials]

- - Wide angle X ray scattering

- - Polarized light microscopy – for inhomogeneous and anisotropic materials

- - Second Harmonic generation imaging [SHG]

- - Fourier Transform Infrared Spectroscopy

- - Confocal Laser scanning microscopy [CLSM]

- - Serial focused ion beam/scanning electron microscopy (FIB/SEM)

Each of these methodologies presents advantages and shortcomings. Choice depends mainly on size, type, material and environment of the scanned object. Continuation of this article will provide analyses of various topics of interest.