A computational approach to design anti-oxidation protection systems for omega 3 oils

Oxidation resistance is one of the crucial features that premium omega 3 supplements must exhibit. Oxidation itself is a degradation of the structure of the poly unsaturated acids that results in shortening their chain, destroying the double bonds, and creating smaller fragments with ketone and aldehyde being the dominant ones. Oxidation itself is a complex group of chemical reactions that are affected by parameters such as:

n Temperature

n Composition of supplement mixture

n Oxygen composition in contact with the omega 3s

n Water / moisture composition in contact with the omega 3s

n Light intensity

n Other impurities or energy sources

Since oxidation is a chemical process, different approaches can be followed to reduce or eliminate its effect. Premium products tend to include at least two layers of protection, whereas low-cost products either utilize one or two layers of protection against oxidation. The main approaches to achieving the goal of reducing or eliminating the oxidation rates can be summarized as follows:

a- Achieve a better ‘starting point’ in terms of anisidine value, peroxide value and similar (TOTOX, etc.). Lower initial oxidation values offer lower oxidation rates due to the absence of oxygen, moisture and free radical concentration in the initial omega 3. This barrier is dependent on the omega 3 manufacturing processes and highlights the importance of the choice of such a manufacturer.

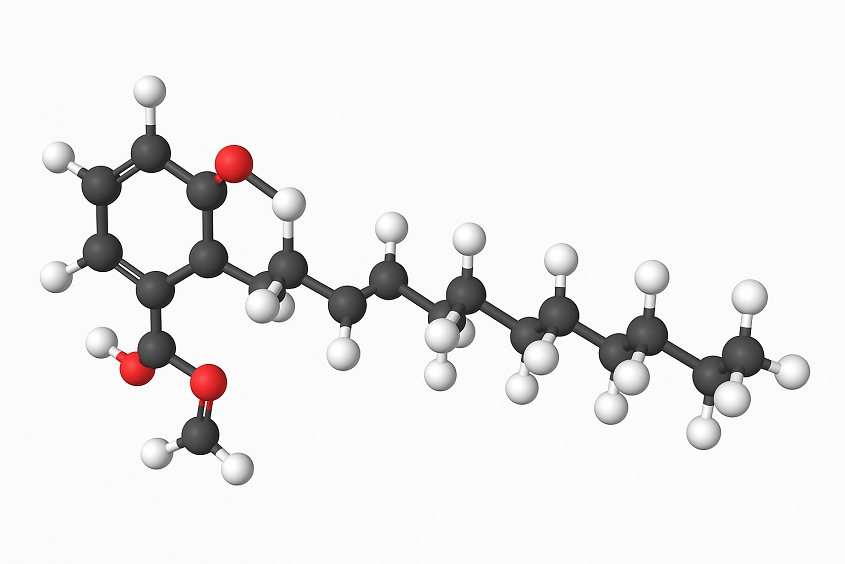

b- The starting point is further protected with the inclusion of antioxidants, such as tocopherols, whose functionality is to bind free radicals and oxygen species before they attach double bonds and functional groups. Antioxidants based protection is the most common scheme employed in the industry today. Little evidence suggests that it can reverse oxidated states, but introduction before oxidation occurs is a great measure for the long-term protection of omega 3s.

c- Use capsules with the lowest degradation and penetration rates for oxygen and water species. Industry standards today are soft gels and hard capsules, but other alternatives exist, including HPMC capsules, Pullulan capsules, etc. Oxidant species penetration is only one feature of interest for the capsules, so commonly other characteristics prevail in the decision-making process [cost, compatibility, and others]

d- Use packaging against oxygen and moisture penetration, most times semi- or non- transparent at all to avoid light exposure. This packaging usually consists of polymeric materials with thickness and the inherent oxygen penetration rates being the governing factors. The resistance to oxygen flow of the packaging is a function of thickness, material, composition of oxygen externally and internally, and of course temperature. This is a process well described by Fick’s equations of diffusion.

e- An individual packing for each or a smaller number of capsules provides an additional resistance to oxidant species towards the omega 3 content. In contrast to bulk packing, the individual packing, although costlier, protects each capsule till the unwrapping time, and thus provides superior protection. The bulk packing is susceptible to oxygen intrusion each time the user opens it to pick a capsule.

f- A final step is the packing process under an inert atmosphere. Most premium brands employ Nitrogen for this purpose, but Argon is a far more prominent choice since it doesn’t leak out of the containers when they are used. Being larger, heavier and monoatomic, its loss rate is very low and offers long-term protection in the bulk container.

We, at MVS Pharma and SinodosChemistry have created inhouse computational tools to predict and optimize oxidation and moisture penetration into the different case scenarios for protection of our omega 3 supplements. The algorithms and codes created take into consideration a series of parameters in simulating the long-term storage and use of our supplements, that include:

n Materials for primary packaging (PP, Paper/PET/LDPE, PP/Metal, Paper/PLA, Paper/Alu/PE, Paper/PE) and their properties of interest (Thickness, OTR, WTR, porosity, among others)

n Materials for secondary packaging (PLA, PET, PP, LDPE) along with their properties of interest (OTR, WTR, porosity, shape)

n Diffusion parameters for oxygen, moisture, and other gases of interest (sizes, Van der Waals radii, diffusion constants, dynamic profiles)

n Oxidation kinetics based on first and second order kinetics

The MVS Pharma and SinodosChemistry approach has led to predicting the lowest oxidation profiles in the market and offering the longest self-life for our products. Our algorithms identify optimization points and predict profiles for all related species and dynamic omega 3 profiles.