Hydrocarbon Cracking and Fluidized Catalytic Cracking simulation and optimization

ON-SITE seminar: Hydrocarbon cracking is one of the vital processes in refineries. Complete understanding leads to ability for design, optimization and control that result to engineering and financial excellence. Environmental regulations, legislation and ethics also call for advanced control of hydrocarbon cracking and minimization of energy consumption and material loss. Catalysis and catalytic cracking processes constitute the cornerstone of hydrocarbon cracking. This scientific seminar focuses on hydrocarbon cracking, catalysis and catalytic processes principles and Fluidized Catalytic Cracking simulation and optimization.

Objectives for attendants:

ü To familiarize with the principles of catalysts and catalytic processes

ü To familiarize with the thermodynamics of catalytic processes

ü To understand hydrocarbon cracking philosophy and approaches

ü To understand the fluidized catalytic cracking approaches and technology

ü To learn about modeling approaches of FCC

ü To understand recent breakthroughs is FCC simulation and optimization

ü To familiarize with FCC simulation in commercial process simulation packages

ü To identify all critical points (factors) in FCC simulation and optimization

Daily Schedule and Contents:

Day 1: Introduction to catalysts and catalytic processes

ü Catalysts, pseudo catalysts and effects

ü Catalytic processes

ü Case studies

ü Physical and chemical attributes: Porosity, active centers, pore size distributions, activation barriers, energetic paths

ü Types of catalysts; zeolites, activated carbons, metals, acids, novel compounds

ü Empirical models of catalytic action

ü Thermodynamics of catalysis

Day 2: Introduction to process desing, simulation and optimization

ü Introduction to process design principles

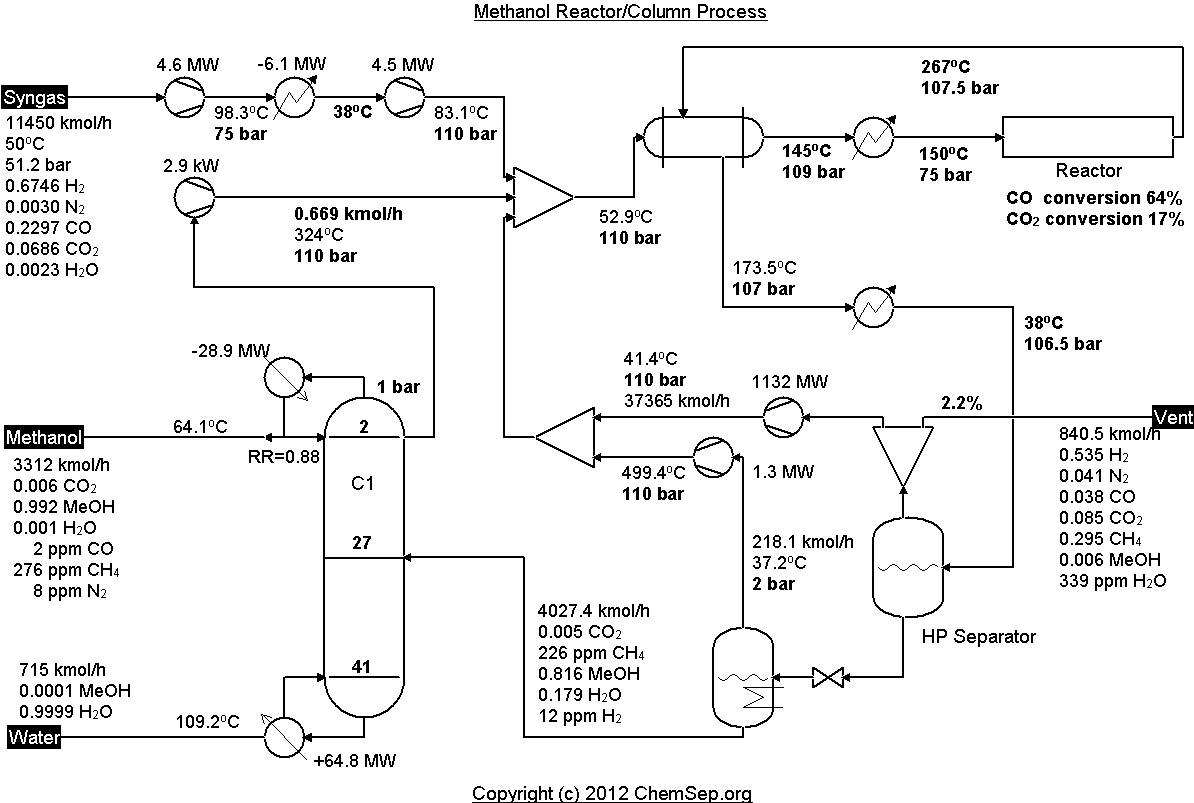

ü Comparison of commercial and custom made process simulators [COCO, Hysys]

ü Introduction to flow charts, diagrams, interconnection of stages

ü Process design

ü Evolution from process design to process simulation

ü Process simulation and optimization [COCO, Hysys]

ü Optimization functions and factors

ü Case studies [COCO, Hysys]

ü Empirical models vs Process simulation

Day 3: Hydrocarbon cracking

ü Hydrocarbon cracking presentation and analysis

ü Discussion of stages and devices

ü Identification of flaws and bottlenecks

ü Different approaches and thermodynamic evaluation

ü Stages of hydrocarbon cracking

ü Chemical species

ü Undesired transformations

ü Aggressive conditions

ü Atomistic modeling of cracking (HyperCube Simulations)

ü Introduction to HyperChem

Day 4: Hydrocarbon cracking

ü Activation and deactivation of zeolite

ü Coke formation

ü Approaches to catalysts deactivation fix, control or avoidance

ü FCC optimization opportunities at CCPs [critical control points]

ü Riser analysis

ü Downer analysis

ü Catalyst regenerator analysis

Day 5: Process design and simulation

ü Design of FCC [COCO, Hysys]

ü Creation of known scenarios in process simulator [COCO, Hysys]

ü Presentation of different conditions

ü Modification of operating conditions [COCO, Hysys]

ü Identifications of issues generation [COCO, Hysys]

ü Case studies [COCO, Hysys]

ü Troubleshooting

Day 6: Process design and simulation

ü Setting up catalytic processes [COCO, Hysys]

ü Setting up non catalytic processes [COCO, Hysys]

ü Comparison of catalytic and non catalytic design, control and optimization

ü Modeling of hydrocarbon mixtures at atomistic level (HyperChem)

ü Investigation of catalytic activity at atomistic level (HyperChem)

Day 7: Kinetics and thermodynamics investigations

ü Mixing model

ü Flow models

ü Reaction models

ü MatLab case studies for different reactors

ü Integration of CFD, Atomistic simulations and Process Simulation

ü Closing and discussion

Who should attend?

ü Chemists, Chemical Engineers, mechanical engineers, industrial engineers

ü Laboratory personnel/ researchers

ü Plant managers

ü Efficiency supervisors